Keep it cool, clean and dry. A smooth abrasive flow with dry compressed air.

Aftercoolers up to 3 m³/min

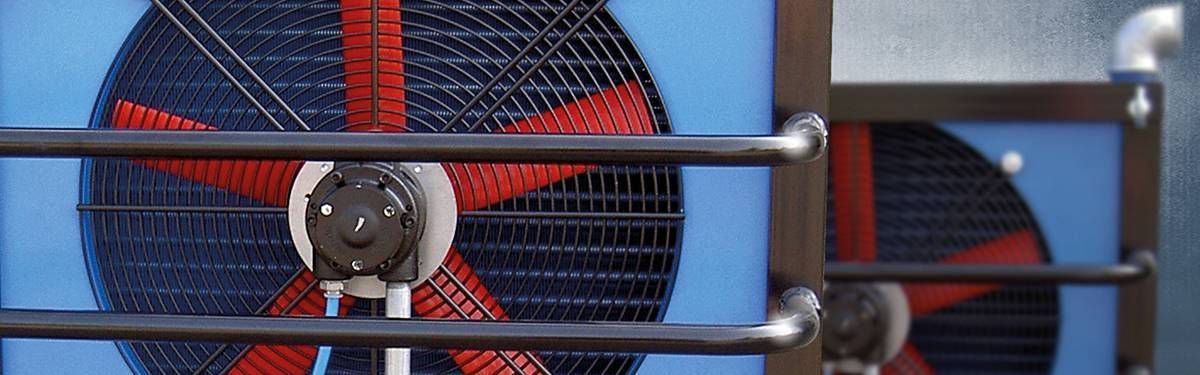

To enable trouble-free blasting the compressed air has to be as dry as possible. Gritco’s range of aftercoolers is designed to get the best possible compressed air, for small, mid-sized or large blasting systems.

To prevent blast pot blockages, secure a smooth, continuous abrasive flow with lesser breakdowns, wear and maintenance, compressed air needs to be cooled down (approximately at 9°C above ambient temperature). Because of this drop in temperature, water condenses and forms drops. These drops are removed by the aftercooler’s centrifugal separator. For even better clean air-results, optional compressed air filters can be fitted to remove oil and other containments.

The aftercooler is fitted with a pneumatic motor for easy everywhere use. For stationary use or compressed air savings an electric motor in 240V is available. Connection to the compressor’s battery is possible with the 12V DC motor for the smaller models.

-

Powerful benefits

- Easy (re)moving and installation

- Quick setup in less than a minute

- Easy to use and accessible drainage system

- Optional automatic drainage

-

Better blasting value

- Trouble-free blasting production because of 80 - 85% moist extraction

- Nominal capacity model range of 1 to 3 m³/min (35 to 105 CFM)

- Minimal pressure drops through large pipework

- Best performance at low energy costs because of optimal fan-design

- Wide choice of (optional) oil- and containment filters

-

Quality includes

- High quality heat exchanger with copper tubes and aluminum fins

- Grid protected cooling fins

- Durable powder coated finish

-

Better blasting economics

- Best possible blasting production because of trouble-free performance with less stops

- Saving on abrasive use by better metering possibilities with a smooth continuous abrasive flow

- Avoid costly, poor blasting results caused by wet compressed air