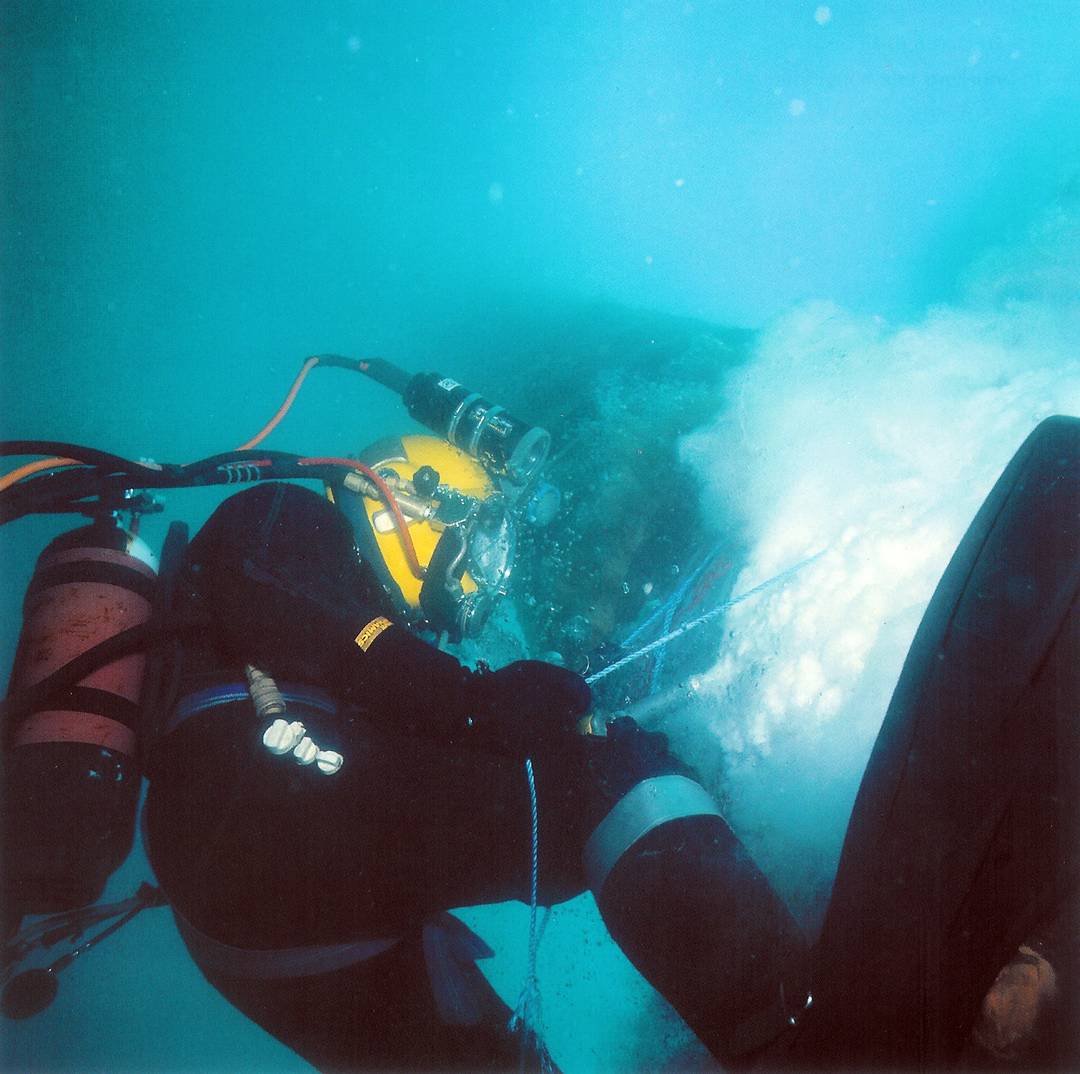

Subsea blasting

This innovative blasting solution offers a significantly safer, quieter and more efficient approach than traditional high-pressure water systems, without the need for retro jets. With very low blasting pressures, the SubSeaSeries is the most cost-effective solution for removing marine growth, paint and rust. Perfect as pre-treatment for inspection but also for an SA 2½ finish.

The blast chain

In the world of underwater blasting, higher blasting pressure is necessary because of the back pressure of the water around the nozzle. Thereby, additional safety features on the machine are essential to ensure a safe working environment for divers.

Choosing the right abrasive and grain size are important factors for efficient underwater blasting.

To achieve the highest possible production rate, large nozzles are used, which also requires the compressor to have a large capacity. As with all blasting operations, it is essential that the compressed air is then dry and clean to avoid blockages and machine problems.

Our blast pots for this

The right blast chain

Achieving the results you want requires the right composition of the blast chain to suit your situation. We can help with that.

In a (free) consultation, we determine together the alignment of the different links to achieve the best results at lower costs.