Experience Centre

Try before you buy! Experience your best blasting solution yourself at Gritco’s unique Experience Center

Try before you buy! Experience your best blasting solution yourself at Gritco’s unique Experience Center

Avoid precious mistakes and do not only gain thorough knowledge of all possible sorts of blasting solutions, but also put them to the test extensively before deciding what is your ideal blasting solution.

You are more than welcome in our brand new and unique Experience Center to get acquainted with Gritco’s wide range of high quality blasting equipment. Experience first-hand what more than 35 years of designing-, developing- and manufacturing has resulted in. And what this could mean for your daily blasting practice.

Suction feed blasting

Vacuum based, multi-functional way of pre- or after blasting objects in blasting cabinets. Often used for repairs or overhaul.

Pressure feed blasting

Most effective and efficient blasting method for removing the heaviest forms of pollution, coatings, mill scale or welding discolouring and/or treating large objects or series of parts. Big variety of air pressure blasting pots but also of air pressure blasting cabinets.

Wet/vapour blasting

Blasting and degreasing at the same time in a blasting cabinet for a high quality, smooth finish of Stainless Steel and aluminium objects. Wet air blasting causes less dust when using blasting pots (without blasting cabinets).

Soda blasting

Baking soda based blasting media removes coatings and containments without damaging or distorting the substrate. Suited i.e. for cleaning high quality industrial installations, components and mouldings.

Fine blasting

Precisely controlled constant dosage of the finest blasting media at low blasting pressure. Very well suited for wood blasting, façade & monument cleaning and fire damage.

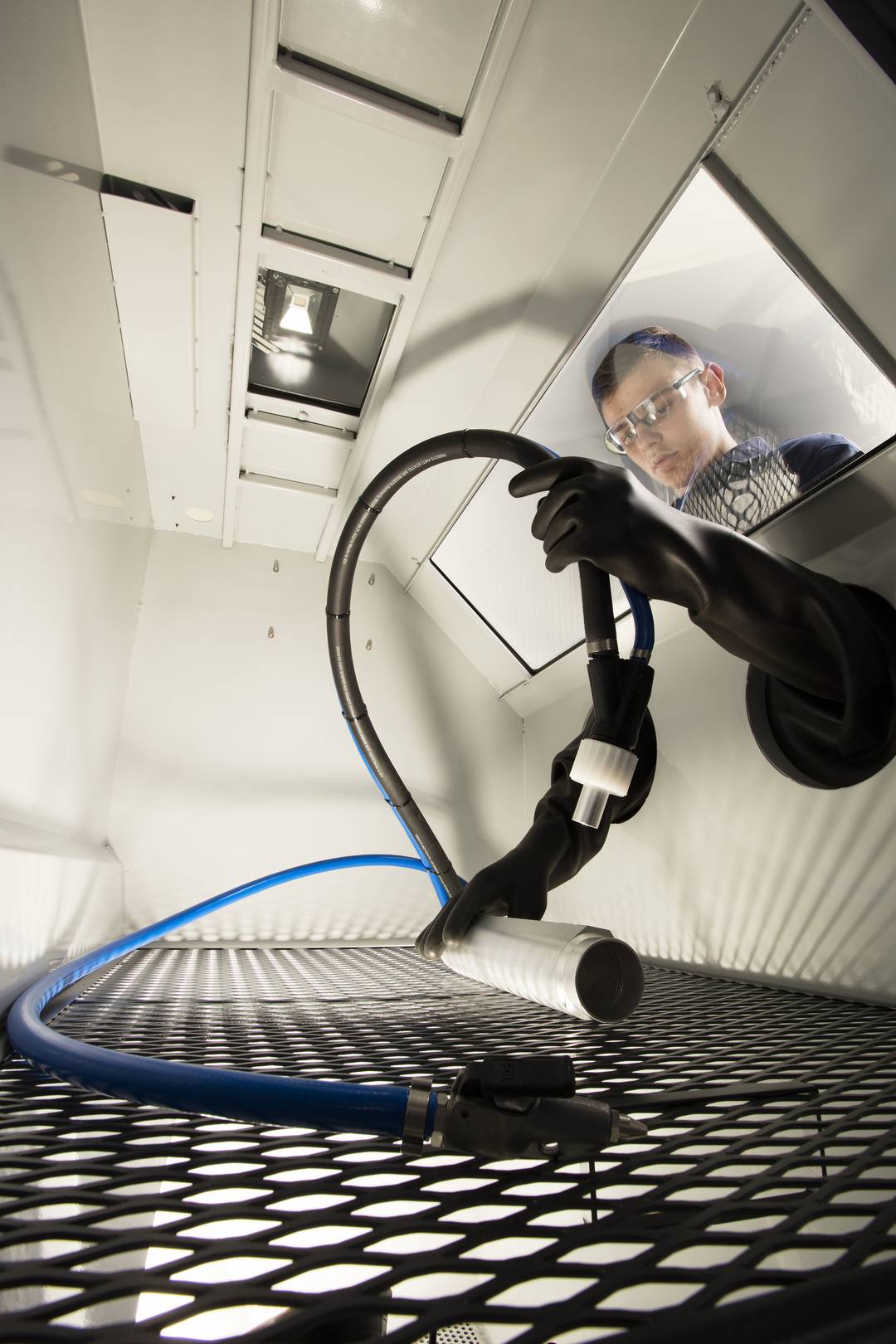

Vacuum blasting

Vacuum, or dust free blasting is suited for spot repairs, welding seams and/or in-situ blasting in working environments where dust- and abrasive pollution is to be avoided.

Put it to the test! Experience first-hand your best blasting solution at Gritco's unique Experience Centre.