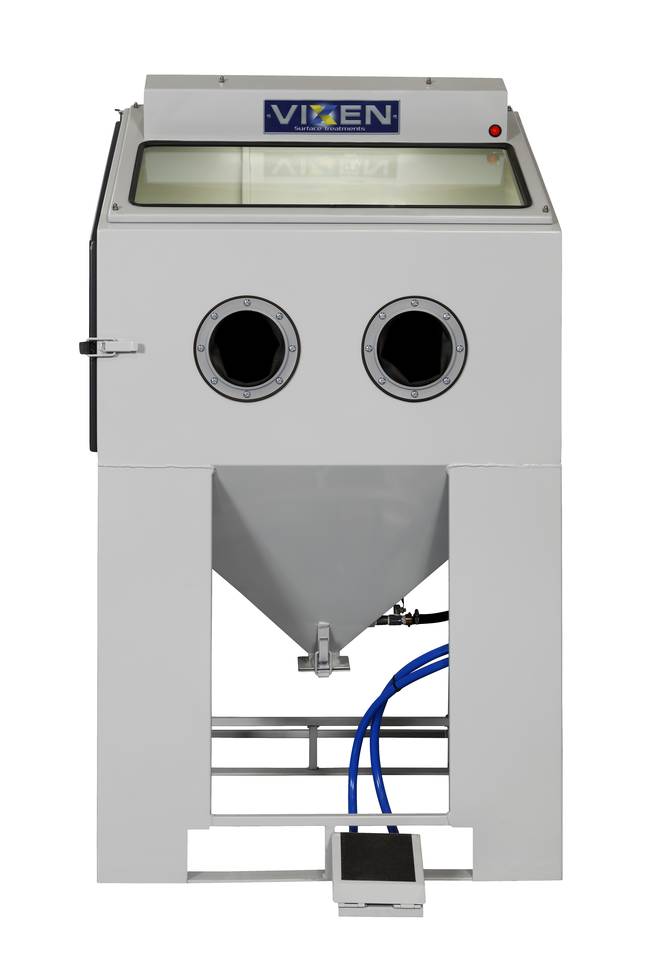

Suction feed cabinets

Suitable for a wide range of different projects. For example, for repair preparation (rust and/or paint removal) or overhaul work (optical embellishing).

Free tailor-made advice

No standard solutions, but tailor-made solutions for every sector. Our experience guarantees the perfect solution for your needs. Wondering how much faster and more thoroughly you can treat products with our injection blast cabinets?

Suction feed blasting

The suction feed (or injection) blasting method works with two hoses, both connected to the blasting gun. One hose supplies compressed air, creating a vacuum in the blasting gun that sucks the abrasive through the second hose.

Good visibility and effective dust control are achieved by the powerful dust extraction system. Depending on the type of abrasive and the application, dust extraction can be further optimised by using automatically cleaned filter cartridges or a cyclone separator.

Powerful benefits

- Optimal work view through full-width window and effective dust extraction

- Large loading space via large side door

- Easy disposal of dust collected in hopper

Request a free proposal

Every company is unique and every blasting application requires an individual approach. Therefore, we are happy to offer a free machine proposal tailored specifically to your needs.